What happens when you take your deer or livestock to the butcher? John Weaver from Makin' Bacon Meat Processing

How Does Meat Processing Work?

John Weaver, the owner of Makin' Bacon Meat Processing in Yellville, Arkansas, is an expert in the field. According to him, the meat processing process typically involves the following steps, as outlined by ScienceDirect:

Animals are brought to a custom-exempt plant, where they are humanely slaughtered following strict regulations and guidelines.

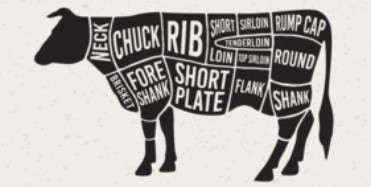

After slaughtering, the dressed carcasses are cut into smaller pieces, such as primal cuts or specific portions like steaks, chops, or fillets. Trimming involves removing excess fat, connective tissue, and bones to obtain leaner meat cuts.

The meat undergoes a thorough inspection to ensure it meets safety and quality standards. Trained inspectors examine the meat visually and may also perform microbial testing to check for any potential contamination or diseases.

The meat is then packaged to maintain its freshness and prevent contamination. Common methods include vacuum-sealing or using airtight containers to extend the meat's shelf life.

Meat can undergo additional processing to create various products based on consumer preferences. This may include grinding the meat to produce ground meat or minced meat, using it as an ingredient in sausages or lunch meats, or marinating and seasoning for ready-to-cook or ready-to-eat products.

John Weaver also mentioned that Makin' Bacon Meat Processing works with a variety of animals, including deer, hogs, beef, lambs, goats, alligators, and elk. Their expertise lies in transforming raw meat into marketable, safe, and attractive products that meet the demands of consumers.

Please note that while John Weaver's expertise and insights are mentioned, it's important to refer to other reputable sources and industry standards to gain a comprehensive understanding of meat processing.

Business Owners in Southwest Missouri and Northwest Arkansas Are Running With the Opportunity for Significant Financial Growth Through 2028

Business Owners in Southwest Missouri and Northwest Arkansas Are Running With the Opportunity for Significant Financial Growth Through 2028

Pioneering Quality in the Steel Industry

Pioneering Quality in the Steel Industry

Can a Contractor Take Over Your Home

Can a Contractor Take Over Your Home

Frozen Pipes, Hot Water Heaters, and Dishwasher Mishaps

Frozen Pipes, Hot Water Heaters, and Dishwasher Mishaps

Choosing the Right Trailer: A Comprehensive Guide

Choosing the Right Trailer: A Comprehensive Guide